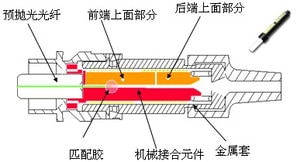

After the optical fiber array is packaged, its section needs to be ground and polished to enable better signal transmission and coupling. This is a key step in determining the final quality of the fiber. Before grinding, it is necessary to fill the optical fiber connector with epoxy glue and then insert the optical fiber. After the glue is cured, the grinding is performed to prevent the edge of the optical fiber from being broken during the grinding process, which makes the optical fiber unusable.

Two-component epoxy adhesive is used in the protection and grinding of optical fiber arrays, and can play the role of bonding and protection. Wanhua Alloy two-component epoxy adhesive, curing at room temperature, easy to apply, and evenly distributed in the micro-hole of the ferrule; excellent adhesion between the bare fiber and the ferrule after curing, low shrinkage and good toughness , Impact resistance, fatigue resistance, chemical resistance and excellent waterproof and moisture-proof performance.

Two-component epoxy adhesive features:

1、It has good adhesion to many substrates, and is suitable for rigid materials such as metals, ceramics, and glass, as well as self-adhesion and mutual adhesion of composite materials and some rigid plastics.

2、Low shrinkage, high hardness, good wear resistance, and excellent electrical insulation properties.

3、The cured bondline has excellent corrosion resistance and chemical resistance.

In the optical fiber industry, two-component epoxy adhesives are often used in the grinding and polishing process of optical fiber connectors and the packaging of optical fiber couplers.

Copyright ? 2020 深圳市宏進科技有限公司All Rights Reserved 粵ICP備20066503

Scan and pay attention to the public number